People

OUR OPERATIONS AND SUPPLY CHAIN

RAG’s high-quality products are produced in numerous countries across the world.

Whilst we do not own or operate factories, we have developed considerable long-term relationships with our valued suppliers and are proud of the working relationships we share.

We collaborate with these suppliers to ensure the working environments in which our products are made are compliant with and align to RAG’s Responsible Sourcing Principles which specifically address modern slavery.

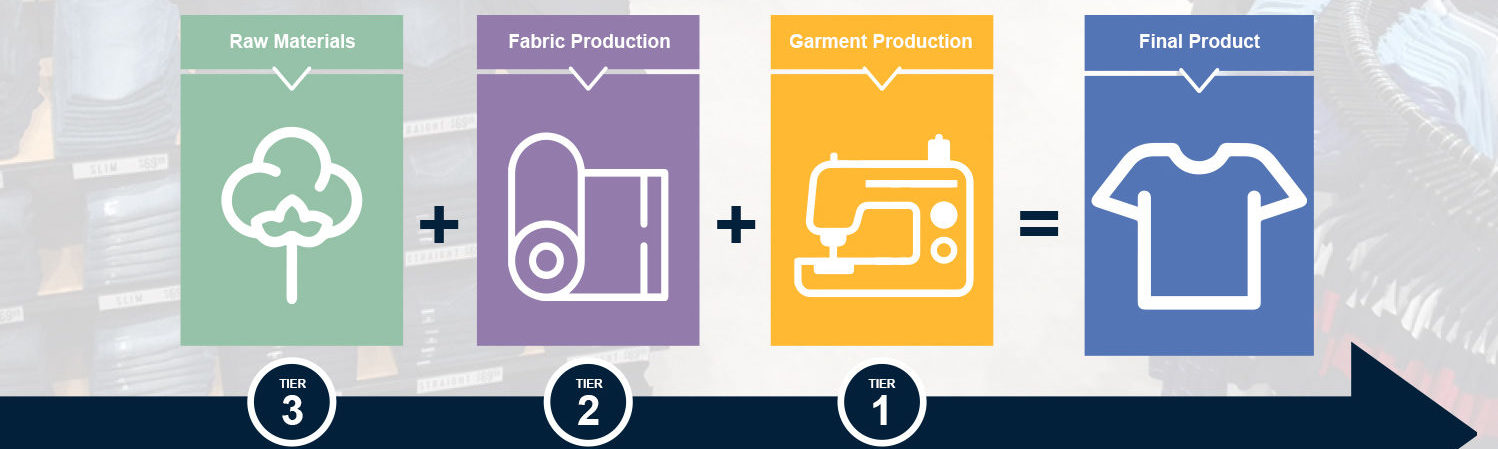

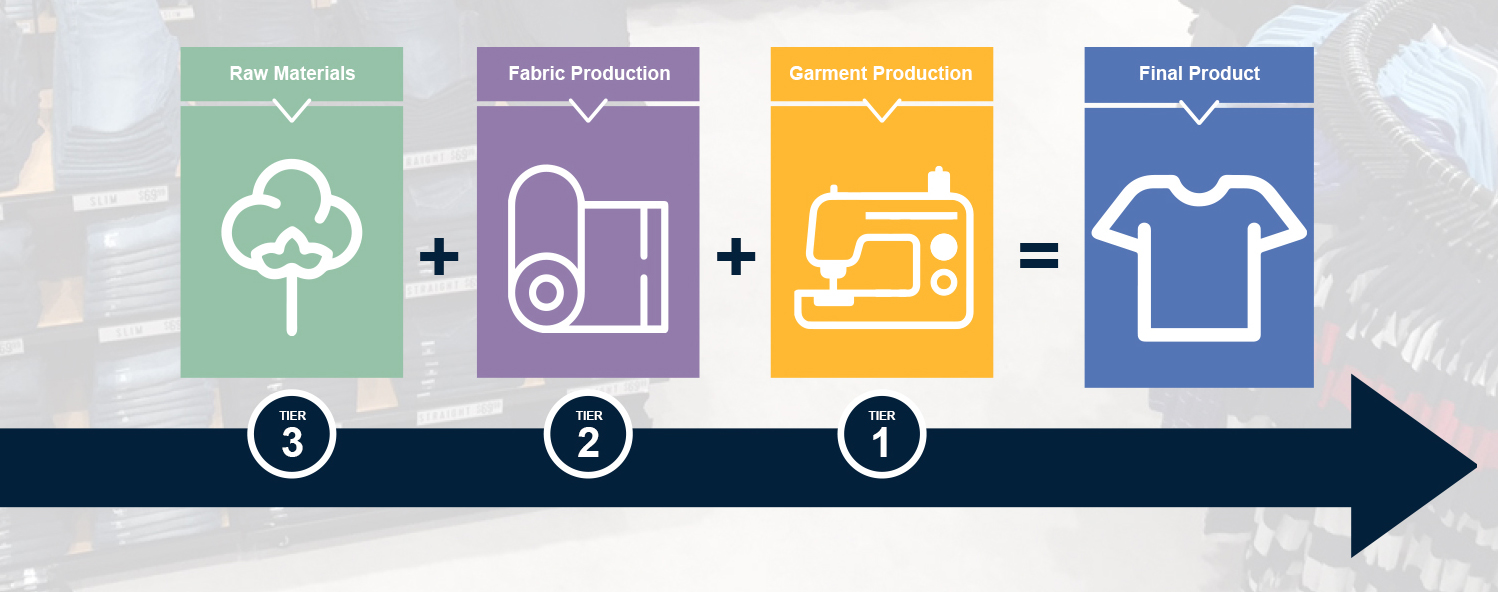

We acknowledge that our supply chains are complex and include various stages, geographies and skill sets to bring our products from raw materials through to finished products. These include the factories where garments are completed; the locations where materials are developed and made into fabric such as in various mills and dye houses; and further down the line, our raw materials which come from farms and various wholesaling relationships.

At present, RAG’s strongest relationships are with the suppliers who are at the final stage of our manufacturing process. As a result, our current procedures focus on addressing modern slavery risks in this labour-intensive process. We recognize that there is a need to continue expanding these procedures further down our supply chain.

STAGES IN PRODUCING OUR PRODUCTS

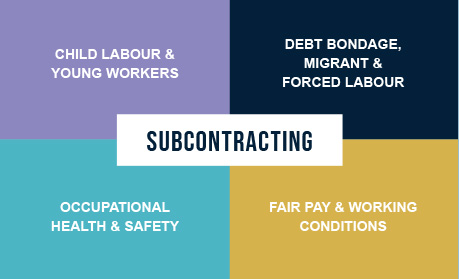

IDENTIFIED MODERN SLAVERY RISKS IN OUR OPERATIONS AND SUPPLY CHAIN

ADDRESSING MODERN SLAVERY RISK: OUR APPROACH